Please select your location and preferred language where available.

History of Yokkaichi Plant

Yokkaichi Plant was established in 1992 and developed as a state-of-the-art semiconductor memory manufacturing facility.

1992 - 2001: Establishment of Yokkaichi Plant

In 1992, Yokkaichi Plant was established as a manufacturing facility for the state-of-the-art memory products of the time, and expected for the development of local economies and industries.

The production site was developed over the course of two years from 1990, and the long-awaited Fab1 started production in 1993. A consistent production line of front-end process and back-end process was constructed, and started production of 16Mbit DRAM, which was the first product at Yokkaichi Plant.

In 1995, Fab2 was constructed and had been designed for further expansion of production capacity and mass production of next-generation products. In 1996, we started production of 64Mbit DRAM, and we made steady progress in expanding our business.

In June 1997, we achieved a cumulative production total of 100million units of 16Mbit DRAM.

As production capacity of 64Mbit DRAM increased significantly, the development of next-generation memory products such as 128Mbit DRAM, 256Mbit NAND flash memory, NOR flash memory and SRAM also progressed.

In 1998, Yokkaichi Toshiba Electronics Corporation, a subsidiary responsible for memory assembly operation, was established. And production of NAND flash memory was started in addition to DRAM and SRAM in 1999. Function of development and manufacturing were concentrated at Yokkaichi Plant, and the production capacity was increased.

However, in 2001, 10 years after its establishment, TOSHIBA Corporation announced its withdrawal from the manufacturing and sale of commodity DRAM due to the impact of the IT recession. Due to this withdrawal, Yokkaichi Toshiba Electronics Corporation was also dissolved. We faced significant challenges in the face of rapid development and change.

|

1992 |

|

|---|---|

|

1993 |

|

|

1996 |

|

|

1997 |

|

|

1998 |

|

|

1999 |

|

|

2001 |

|

Keyword: Yokkaichi City

Yokkaichi City in Mie Prefecture where KIOXIA Yokkaichi Plant is located, is one of Japan’s leading industrial cities blessed with a rich natural environment, abundant human resources, and an outstanding industrial base.

2002 - 2011: As NAND flash memory market grows

In 2002, the semiconductor memory business relocated “Flash Vision LLC,” the joint venture company with SanDisk Corporation (currently Western Digital Corporation), which manufactures NAND flash memory, to Yokkaichi plant, and moved the facilities and equipment in Dominion Semiconductor, L.L.C. A new challenge to steer toward high-value memory products, especially NAND flash memory, began. Around that time, the market for NAND flash memory has grown explosively due to the widespread use of digital cameras and mobile phones with camera. In order to meet market needs, we quickly built a high-productivity structure, and we also worked to improve quality of products. We acquired ISO9001 in 2003, and solidified the production foundation.

In 2005, Fab3, which supported 300mm wafers and had high production efficiency, started operations one year ahead of the original schedule. And we achieved a cumulative production total of 1billion units of NAND flash memory (64MB conversion) in this year. We have increased our production capacity by miniaturizing the production process of NAND flash memory and multi-level cell technology, to meet the increasing storage capacity for images and music.

In 2006, we began construction of Fab4, which installed the latest equipment at the time, and increased our presence in the global market for products from Yokkaichi Plant.

As the memory business performance showed a V-shaped recovery, Fab4, which was world-class manufacturing capability in scale at the time, started operations in June 2007, and mass production was promoted at a rapid pace in response to the expectations of the entire company. On the other hand, in July 2008, due to the failure to notify the High Pressure Gas Safety Act, Yokkaichi Plant received a warning from Mie Prefecture. We took measures to prevent recurrence so that the situation would not happen again, and all employees re-launched with a pledge to thoroughly enforce the “Compliance and safety, first” and to restore trust. Under such circumstances, the research and technology development division of next-generation memory products "Advanced Memory Development Center" was transferred to Yokkaichi Plant and started in earnest. Research and technology development and mass production were integrated as the lifeblood of future business development. We also decided to construct Fab5 for business survival in the world. However, around that time, the global economic downturn and sluggish consumption affected the semiconductor market, and the environment surrounding the memory business increased in severity.

In 2010, construction of Fab5 started as market conditions recover. Toshiba LSI Package Solutions Co., Ltd. moved to Yokkaichi Plant to strengthen the assembly operation. In the same year, the production in 200mm wafers, which produced many memory products to the world was terminated around 18 years of business.

In April 2011, Fab5 was completed long-awaited construction. In September of the same year, we achieved a cumulative production total of 10billion units of NAND flash memory (1GB conversion.) In addition, we started mass production of the world’s first and smallest 19nm NAND flash memory. We have responded to market needs and growing demand by promoting miniaturization and acceleration.

|

2002 |

|

|---|---|

|

2003 |

|

|

2005 |

|

|

2007 |

|

|

2008 |

|

|

2011 |

|

Keyword: NAND Flash Memory

KIOXIA invented the world’s first NAND flash memory in 1987 and is one of the world’s leading developers and manufacturers of flash memory. We started NAND flash memory production at Yokkaichi Plant in 1999.

Keyword: Multi-level Cell Technology

One of the technologies that increases the capacity of flash memory is “multi-level cell technology”, which increases the amount of data stored in each memory cell.

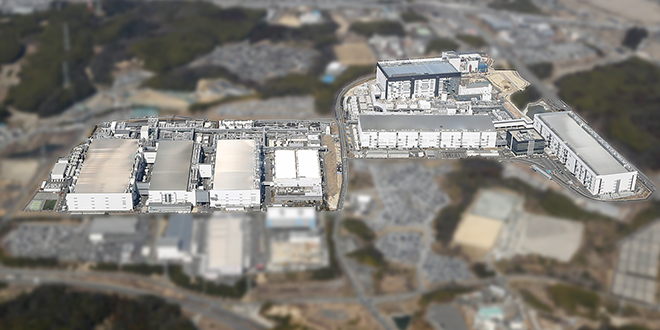

2012 - 2021: Rapid increase of production capacity and transition to 3D flash memory

As technology and cost competition intensified, we completed Fab5 (Phase1) construction in 2011, completed Fab5 (Phase2) construction in 2014, rebuilt Fab2 in 2016, and completed Fab6 and Memory R&D Center construction in 2018, resulting in a construction rush. Each fab is connected by an inter-building transport system to perform integrated production that complements the capacity of manufacturing equipment. In addition, in response to miniaturization, large capacity, downsizing, and low cost required by the market, the research and technology development division and mass production division have closely work together on the same site, and are now able to cooperate quickly.

As a result of our efforts to improve productivity and quality with the aim of realizing “the world’s most advanced semiconductor memory fabrication facility”, we received the “GOOD FACTORY Award for Factory Management (Japan Management Association(JMA))” in 2013. The award recognized the factory’s efforts to establish a management system including a management index, training of technicians and engineers, the use of IT to promote productivity, and an awareness of the environment in its operations. In addition, in 2016, we received the “Gold Prize of Field Innovation Award (The Japanese Society for Artificial Intelligence.)” The award recognized the improvements in manufacturing productivity through AI-based analysis of big data collected from manufacturing and inspection equipment.

The limits of cell size scaling are beginning to be seen, and mass production of 3D flash memory was finally started in 2016. The production capacity of Yokkaichi Plant has grown exponentially due to the rapid increase in memory capacity and the sophisticated manufacturing process technology.

|

2012 |

|

|---|---|

|

2013 |

|

|

2014 |

|

|

2016 |

|

|

2017 |

|

|

2018 |

|

|

2019 |

|

Keyword: Smart Factory

With the rapid increase in memory capacity and complexity and scale of manufacturing processes, some of the data analysis that has been performed by skilled technicians has been automated using artificial intelligence and machine learning.

2022-: Towards a more sustainable semiconductor memory plant

With local residents and all other people’s understanding and support, Yokkaichi Plant celebrates our 30th anniversary in 2022. We promote new Fab7 operation in the future.

We will continue to provide flash memory that is essential to your life and continue to prioritize environmental protection and social initiatives, thus fulfilling expectations regarding our corporate responsibility. We will endeavor to help realize a better global environment and contribute to the development of sustainable society.

|

2021 |

|

|---|---|

|

2022 |

|

Keyword: Sustainability

Introducing KIOXIA Group's Sustainability that contribute to the development of a sustainable society.