Please select your location and preferred language where available.

High-speed UFS 4.0 automotive storage -

accelerating the evolution of autonomous driving technology

Reprinted from: EE Times.com / EE Times.eu

Reprinted from content published in EE Times.com / EE Times.eu on January 31, 2024

This content is used with permission from EE Times Japan.

Department names and titles are as of the time of the interview.

Developed by KIOXIA, the inventor of flash memory

The evolution of autonomous driving technology is leading to an ever-increasing amount of data being used by vehicles. This requires high-performance storage that can cope with the reading and writing of vast quantities of data. In a move that addresses these demands – and creates a better user experience – KIOXIA has developed automotive storage that complies with the new Universal Flash Storage (UFS) 4.0 standard.

Advanced storage requirements driven by the evolution of the automobile

Autonomous driving technology is evolving rapidly toward the ultimate goal of fully self-driving vehicles. Practical implementations of Level 3 technology (“conditional driving automation” under the definition used by the US-based SAE) have already been achieved, and major automotive manufacturers began offering models with Level 3 functionality in 2021.

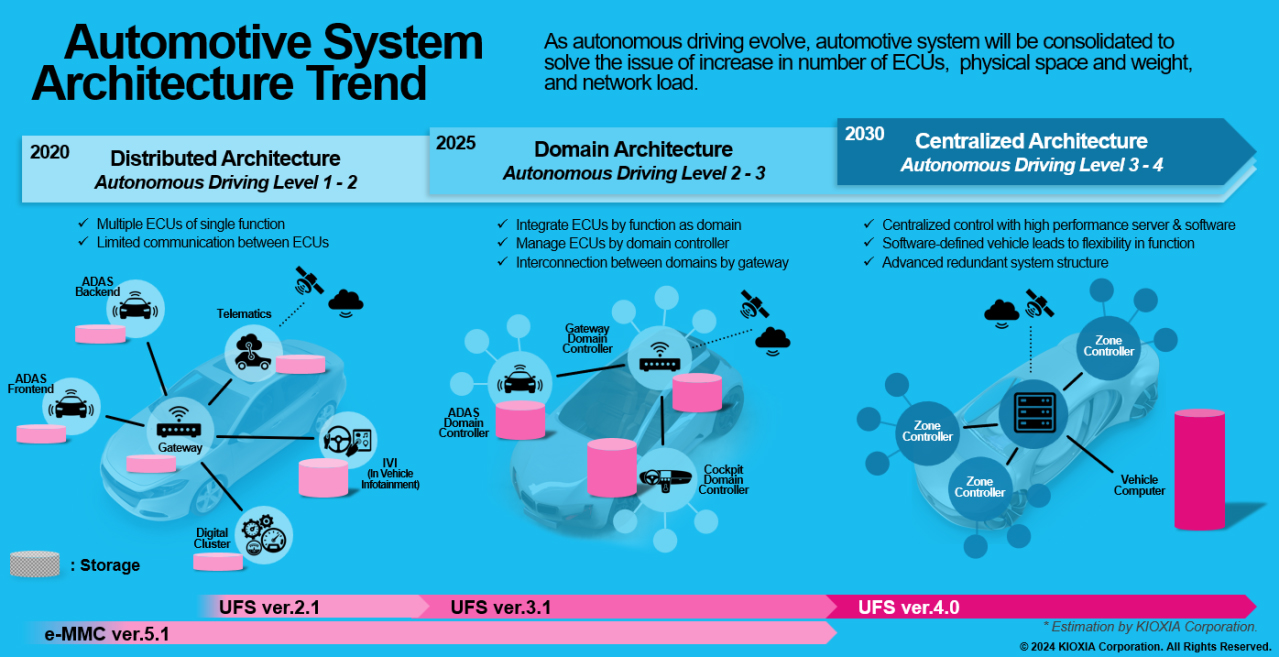

This is also driving the transition to the next generation of vehicle E/E (electrical/electronic) architecture. The objective is to consolidate the ECUs (Electronic Control Units) and vehicle networks that continue to increase as a result of new functionality such as ADAS (Advanced Driver Assistance Systems) and infotainment.

In traditional vehicles without driving automation or support functions, the mainstream approach was a distributed architecture involving the placement of single-function ECUs in required locations. Many vehicles that make extensive use of ADAS and other Level 3 systems have adopted a “domain architecture” approach whereby ECUs that draw together a range of functionality are assigned to each functional area. As the level of driving automation increases, this is expected to shift to a “centralized” approach under which the main domain ECUs are integrated into central ECUs that act like servers, and are capable of dealing with heavy processing and control requirements.

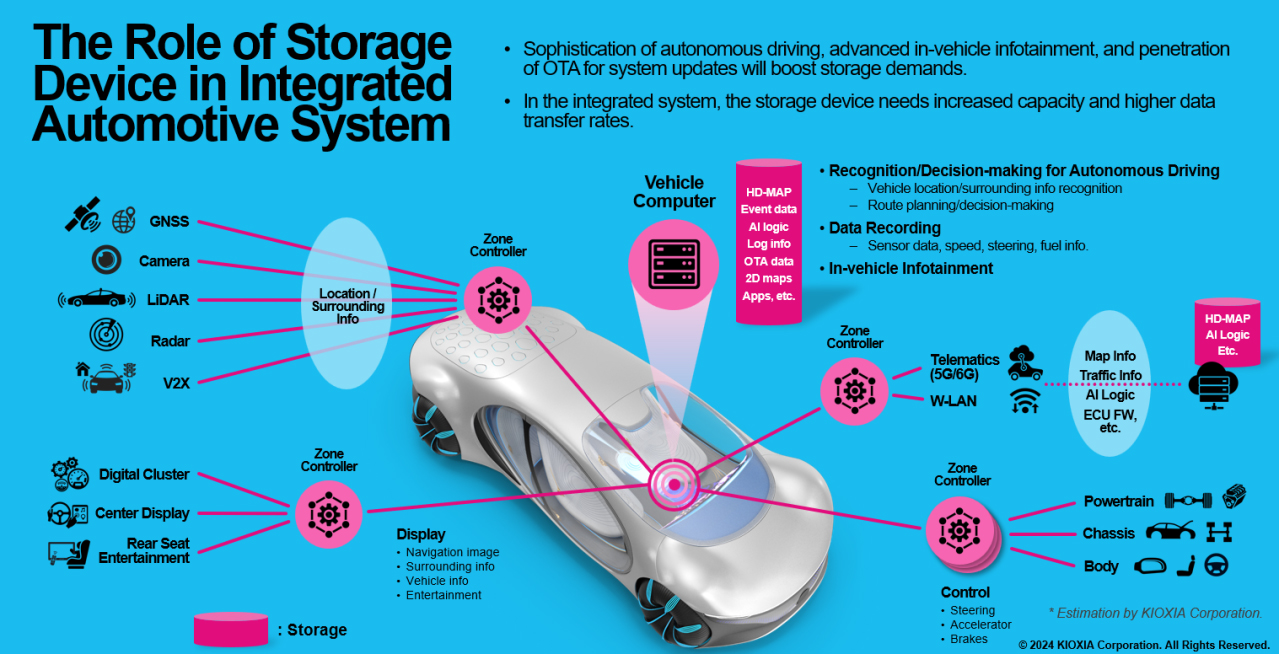

Data storage is a vital component of this evolution in E/E architecture. The move to domain and centralized architectures requires an increase in the speed of the networks used to connect ECUs. Additionally, huge volumes of data are required, such as camera and LiDAR (Light Detection And Ranging) sensor data used in ADAS and autonomous driving, high definition map data, information from other vehicles and pedestrians (V2X), and machine learning models used for artificial intelligence. Functions such as these have created a remarkable increase in the amount of data written to and read from the storage in the ECU. This has led to the need for automotive storage that can handle large volumes of data transfers at high speed.

Automotive E/E architecture is transitioning from the distributed architecture on the left to the centralized architecture on the right. This is driving a reduction in the number of automotive storage devices (shown in pink in the figure) but an increase in their capacity, as well as a requirement for high-speed reading and writing of data. (Source: KIOXIA)

KIOXIA has developed high-performance automotive storage that addresses these needs and complies with the latest storage standard.

KIOXIA, the inventor of flash memory

KIOXIA is the inventor of NAND flash memory and is focused on “Uplifting the World with ‘Memory’”. Flash memory is the quintessential “non-volatile” memory, which retains data stored on it even when the power is switched off. Memory cards and other storage devices that use flash memory are lightweight, shock-resistant, and low power. Because it can easily contribute to the downsizing of systems, flash memory is used in most electronic equipment and systems, from consumer devices such as PCs, smartphones, and household electrical goods, to vehicles and data centers. This highly innovative, extensible technology has shaped the development of products that change the way we live, work and play.

KIOXIA has been a leader in the flash memory and SSD industry since it first invented NAND flash memory more than 35 years ago. In 2007, the company announced 3D flash memory, which offered a new technology evolution in an industry for which memory cell miniaturization had come to a dead end.

In automotive storage, KIOXIA has proactively worked to extend its lineup of products compliant with the embedded Multi-Media Card (e-MMC) and UFS standards. The company began shipping e-MMC products for automotive use in 2013, and UFS for automotive use in 2017. KIOXIA’s automotive storage products have an extensive track record in a wide range of automotive applications, including infotainment systems, ADAS, telematics, and digital instrument clusters.

Continuing to demonstrate its leadership role, KIOXIA has announced products compliant with the latest UFS 4.0 standard for automotive storage.

Achieving higher serial communications speeds with UFS

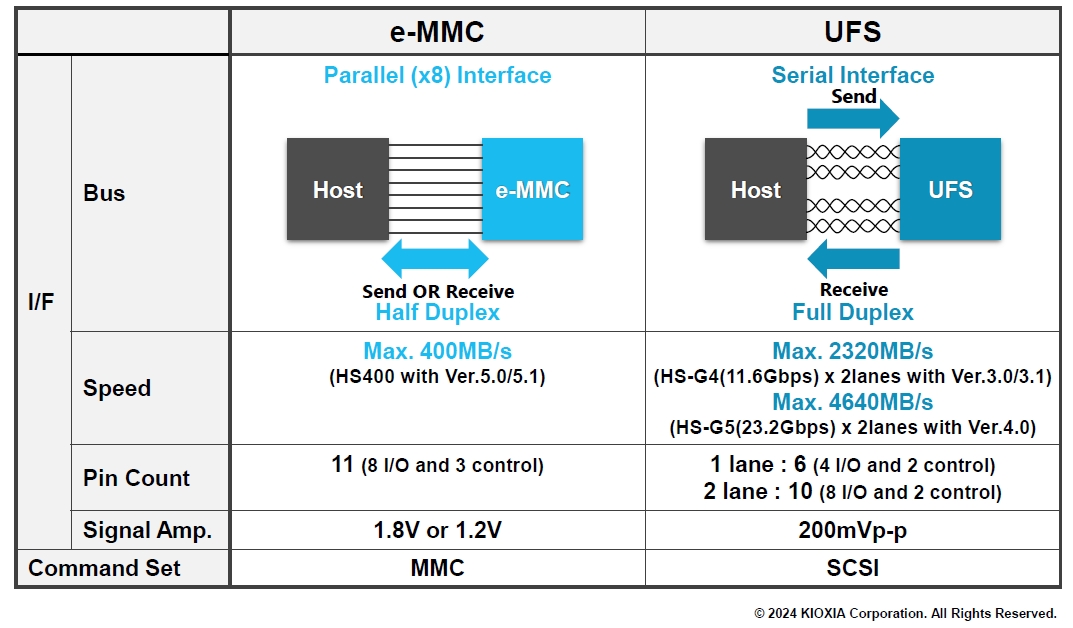

UFS is the successor to the e-MMC storage standard. Both e-MMC and UFS are JEDEC standard specifications, with a key feature being the integration of flash memory and a controller in a single package.

e-MMC, which became a standard in 2007, is still used in many consumer, industrial, and automotive devices. However, transfer speed of e-MMC is limited to no more than 400MB/s due to its parallel interface. This has increasingly led to e-MMC being unable to keep up with high-end smartphones and other devices that require higher operating speeds.

In 2011, the UFS standard was introduced, which uses a serial interface. Because the interface supports full-duplex communication, the host device can read and write data to the storage medium simultaneously. This enabled transfer speeds to be increased significantly over those of e-MMC, with UFS 3.1 (released in 2020) topping out at 2320MB/s, and the most recent UFS 4.0 version achieving transfer speeds of 4640MB/s.

Comparison of e-MMC and UFS. The use of a serial interface in UFS leads to higher data transfer speeds. (Source: KIOXIA)

The adoption of UFS, which began with mobile devices, is also spreading to automotive applications. The mainstream for Level 3 vehicles has been storage that complies with UFS 3.1, but many automotive manufacturers are considering to adopt UFS 4.0 in preparation for future vehicles that will require high-speed data transfers.

Taking the lead in launching UFS 4.0-compliant automotive storage

KIOXIA engaged in the development of UFS products at an early stage. The UFS serial interface makes use of the MIPI Alliance’s M-PHY standard for its physical layer, and the UniPro protocol for its M-PHY interface. KIOXIA participated in the creation of the M-PHY/UniPro specifications, and was also involved in the standardization process.

KIOXIA has been at the forefront of UFS memory since the company announced UFS 1.1 in 2013 and began shipping samples of UFS 4.0 in June 2022 for mobile use. Parallel to the preceding UFS products, KIOXIA started to ship samples of UFS 3.1 compliant products for automotive use in March 2022.

Most recently, the company has begun to ship samples of UFS 4.0-compliant storage products for automotive use. Tetsuya Yamamoto, Director of Memory Application Engineering Dept. 1, Memory Technical Marketing Managing Department, Memory Division at KIOXIA, emphasizes that the company was one of the first in the industry to announce such products.

“We were actively involved in drawing up the M-PHY/UniPro specifications for UFS 4.0, and we tackled development with the aim of launching UFS 4.0 automotive products as quickly as possible. It was partly because we were able to fully utilize our advanced engineering capabilities in the area of M-PHY and UniPro that we succeeded in developing products so quickly,” he comments.

KIOXIA’s UFS 4.0 automotive products can handle an operating temperature range of -40 to 105℃, which is compliant with Grade 2 of AEC-Q100, and achieve speeds of up to 4000MB/s and 2000MB/s for reading and writing, respectively(1). Read performance is approximately twice that of KIOXIA’s previous-generation(2) UFS 3.1 automotive products.

“The key is the performance of our flash memory itself and the flash memory controller technology,” says Yamamoto, explaining these performance gains.

Tetsuya Yamamoto, Director of Memory Application Engineering Dept. 1, Memory Technical Marketing Managing Department, Memory Division at KIOXIA

Wakaki Mori, Manager of Memory Application Engineering Group 2, Memory Application Engineering Dept. 1, Memory Division at KIOXIA

Wakaki Mori, Manager of Memory Application Engineering Group 2, Memory Application Engineering Dept. 1, Memory Division, notes that the company uses fifth-generation BiCS FLASH(3) 3D flash memory as the core technology for its flash memory. “Right from the start we were looking at expanding into automotive UFS products, and we designed them to be capable of operating at high temperatures. We began mass production of BiCS FLASH 3D flash memory for automotive applications in 2023, so in terms of manufacturing the technology is mature,” he observes.

One of KIOXIA’s strengths is that it also designs its own controllers. The controller plays a crucial role in realizing optimum flash memory performance and enabling storage products that come close to the maximum figures defined under UFS and other standards.

While other flash memory manufacturers may use third-party controllers, KIOXIA has insisted on designing its own controllers right from the start, explains Yamamoto. “The controller is responsible for the fine-grained control and management of flash memory, and is one of the most important determinants of storage performance. Developing a controller for high-performance storage is not feasible without extensive knowledge of flash memory,” he says.

“In addition to the analog elements, such as the physical layer, digital circuit technology is indispensable for adding functionality and reducing the power consumption,” explains Mori. “This was also the case for the recently developed UFS 4.0 automotive products, for which we optimized the controller against the standard. The controller technology was particularly effective in accomplishing the maximum write speeds of 2000MB/s. Clever sequencing enabled us to achieve efficient writing.”

In addition to supporting HS-LSS (High Speed Link Startup Sequence) to allow the system to start rapidly, KIOXIA’s UFS 4.0 automotive products are equipped with features to achieve the enhanced reliability and durability that automotive systems require, such as diagnostic functions to check the device’s operating history, and functions to refresh and maintain the reliability of degraded data. The products are offered in capacities of 128GB, 256GB and 512GB(4).

The above is a conceptual diagram of the centralized or E/E architecture. Vast quantities of data move back and forth over the vehicle network, including positional information, information on the surrounding environment obtained from sensors, and map information. An ECU that plays a role similar to that of a server is located in the center, using high-performance storage such as a UFS 4.0 automotive product. (Source: KIOXIA)

Using flash memory to support the evolution of applications

Yamamoto emphasizes that it is KIOXIA’s mission as a flash memory manufacturer to take the lead in developing memory and storage products based on the latest standards. “In terms of UFS 4.0 automotive products, until we develop these, manufacturers developing host SoC (System on Chip) devices to comply with UFS 4.0 cannot even evaluate their SoCs. It would be unacceptable to allow memory to become the bottleneck in the development of the latest equipment and systems by manufacturers. This is something we keep in mind at all times.”

Mori agrees. “In order to contribute to the automobile industry by enabling the early adoption of UFS 4.0, we are working with our ecosystem partners to accelerate mass-production of UFS 4.0 automotive products.”

Moving forward, automotive systems will continue to evolve towards the goal of Level 5 (fully autonomous driving). Functionality will be continuously upgraded through smartphone-style updates, which will result in vehicles implementing improvements that are noticeable to users, such as being able to traverse a particular curve more smoothly than they did previously. KIOXIA’s UFS 4.0 automotive products will undoubtedly contribute to that evolution through their ability to read/write large quantities of data at high speed. “We are confident that our UFS 4.0 automotive products, which reflect our unparalleled flash memory know-how, will meet or exceed customer expectations,” says Yamamoto.

Notes

- MB/s is calculated as 1,000,000 bytes/s. Read and write speeds are the best values obtained in a specific test environment at KIOXIA and KIOXIA warrants neither read nor write speeds in individual devices. Read and write speed may vary depending on device used and file size read or written.

- Comparison is with KIOXIA’s previous-generation THGJFGT2T85BAB5.

- “BiCS FLASH” is a trademark of KIOXIA Corporation.

- Indicated product capacity is based on flash memory, and does not show actual capacity available to the user. Part of the capacity is used for management purposes. Please check product specifications to ascertain actual capacity available to the user. Memory capacity is calculated as 1,073,741,824 bytes for 1GB.